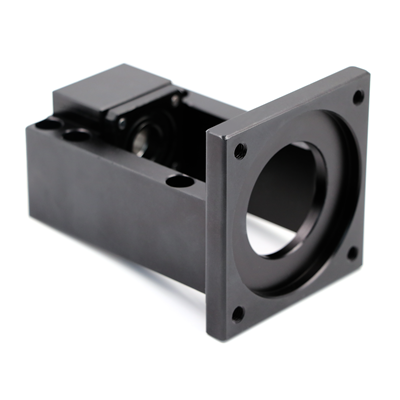

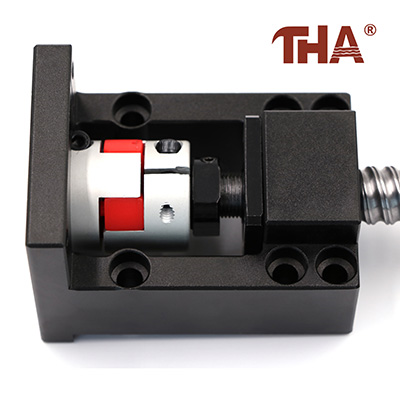

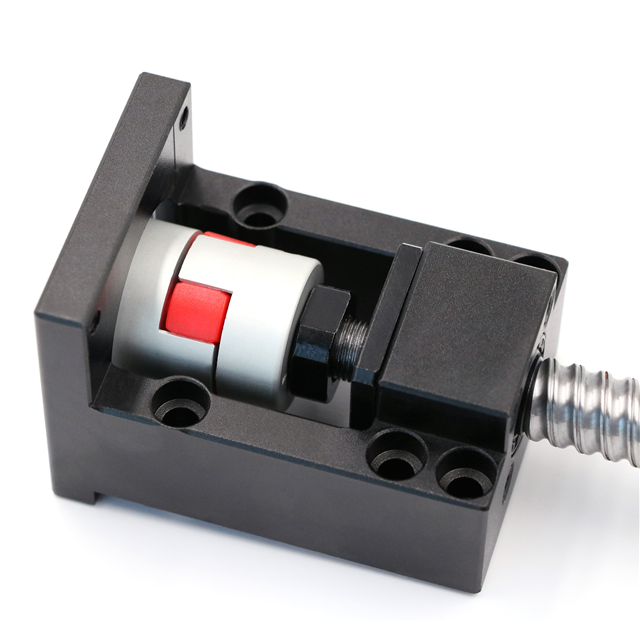

Integrated motor mount positioning holes and the fixed bearing end support block mounting hole take the integrated processing, to ensure motor shaft, coupling axial, axial bearing hole, and ball screw axis all in a line strictly, make the ball screw kit anad the transmission system run more accurately, less noise and longer life.

Product Details

Lishui Guangyuan Industry & Trade Co., Ltd. is one of the professional manufacturers and suppliers of professional CNC accessories in China. If you are going to check the price of Stepper Motor Bracket in China, please feel free to contact us at any time. The advantages of our stepper motor bracket are easy installation, high positioning accuracy, and high precision.

Product Description

a. Easy to install and use. The bearing seat and the motor seat are processed in one piece, and they are directly centered after installation, eliminating the need for adjustment steps.

b. Strict shape and position tolerances, and all shape and position tolerances of the overall finishing are strictly controlled.

c. The technical status is stable and interchangeable.

d. High rigidity and strong impact resistance.

| Product Information | |

|

Product Name |

Stepper Motor Bracket |

|

Material |

Aluminum Alloy Motor mount bracket |

|

Advantages |

1. Simple installation: equipped with a unit, the motor can be easily installed using the connector. 2. High precision: The ball screw and the mounting part of the motor are integrated. This structure can effectively reduce the error between the two shafts. 3. High positioning accuracy: The connecting piece is equipped with a special ball screw support seat, which can effectively control the axial movement of the screw. 4. High rigidity: The connecting parts are made of high-quality medium carbon steel, which has strong impact resistance and durability. |

|

Model No. |

BC12ZC/AC-57, BC12ZC/AC-60, BC15ZC/AC-80, BC15ZC/AC-86 |

|

Size Available |

Nema23,Nema34 stepper motor, and 60.80 servo motor |

|

Product Package |

a. Plastic bag with box case or wooden case. We can provide shipping information to our customer at any time. |

|

Delivery time |

3~7 days for sample order, 15~20 days for bulk order. Depends on the actual shipping situation. |