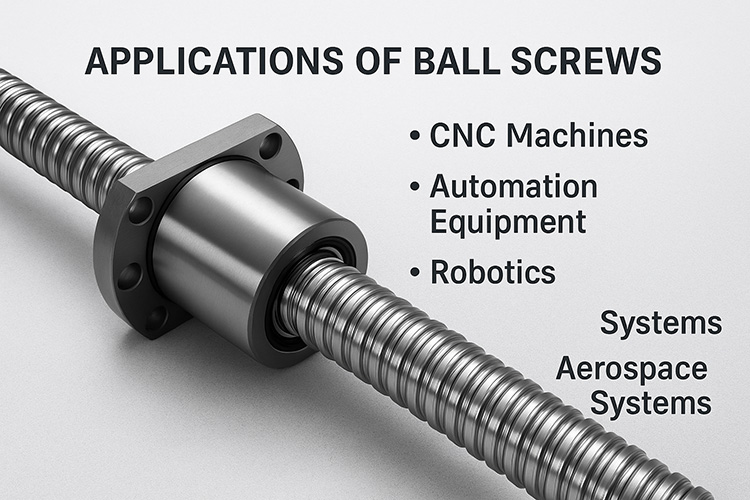

As an indispensable transmission component in CNC machine tools, ball screws play a pivotal role in the performance of the entire machine. Whether in the field of mold processing that pursues extreme precision or in production lines that require continuous and efficient operation, the performance of ball screws will directly and profoundly affect the overall quality of CNC machine tools. So, how to improve the production efficiency of high-precision ball screws? This is a question worth thinking about.

First, we can use advanced processing technology: introduce advanced processing technologies such as high-speed cutting and precision grinding to improve processing speed and precision.High-precision ball screws combined with advanced processing technology can achieve twice the result with half the effort.

Secondly, improve the process flow: conduct a detailed analysis of the existing production process and remove unnecessary links. By rationally arranging the process, we can reduce the handling and waiting time of workpieces between different equipment, making the production process smoother. We can also optimize tools and fixtures: selecting appropriate tool materials and tool geometry parameters can improve cutting efficiency and quality and extend tool life. At the same time, designing precise and efficient fixtures can quickly locate and clamp workpieces, reduce clamping time, and improve processing accuracy and stability.In this way, the ball screw can function more smoothly and efficiently in the production process.

Then we need to pay attention to the upgrading and maintenance of equipment: regularly evaluate production equipment, replace old and low-performance equipment in time, introduce advanced production equipment and automated production lines. At the same time, establish a complete equipment maintenance system to ensure that the equipment is in good operating condition and reduce equipment downtime.

In addition to these, ball screws also require irregular maintenance and cleaning, regular replenishment of grease or lubricating oil, and protection from foreign matter such as dust and water vapor. Through the above measures, the production efficiency of high-precision ball screws can be effectively improved while ensuring the quality and performance of the products.

Welcome to contact us!!!

gykristyliu@gmail.com

sales@gyballscrew.com

![]()

![]() Whatsapp/wechat:17769815516/18967093658

Whatsapp/wechat:17769815516/18967093658

![]() Email: tha@gyballscrew.com

Email: tha@gyballscrew.com