|

Product Information |

|

|

Product Name |

Factory High Hardness Gcr15 Linear Shaft |

|

Material |

Bearing steel guide, bearing steel aluminum base, GCr15 Bearing steel |

|

Length |

can be customized according to customers requirement |

|

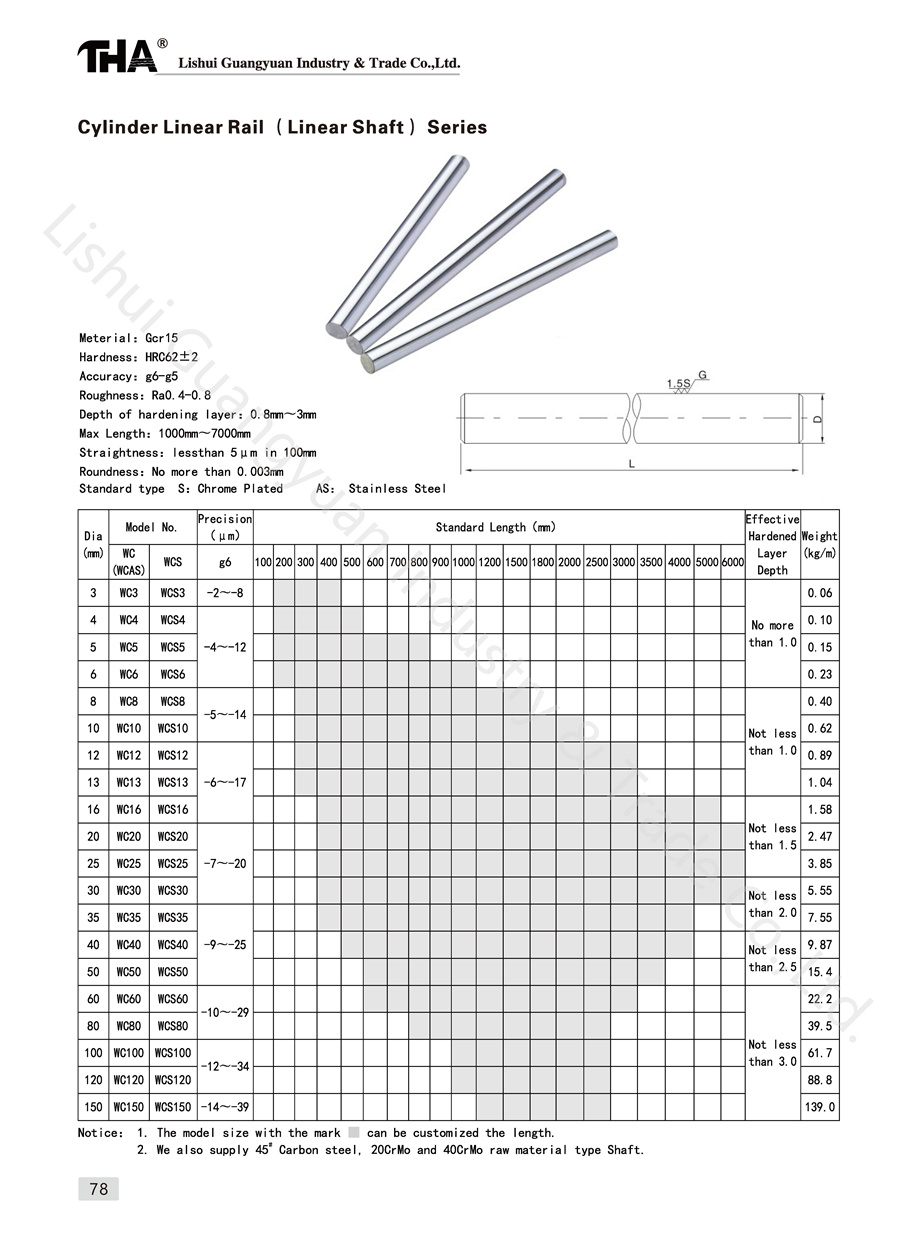

Model No. |

Diameter (mm): 3, 4, 5, 6, 8, 10, 12, 13, 16, 20, 25, 30, 35, 40, 50, 60, 80, 100, 120, 150 |

|

Precision Processing |

Drilling, Milling, CNC Turning, Grinding, Wire Cutting, EDM & etc. |

|

Surface Finish |

Anodize, Polishing, Zinc/ Nickel/ Chrome/ Gold Plating, Sand Blasting, Phosphate Coating & etc. |

|

Part Color |

Silver, Red, Blue, Gold, Oliver, Black, White & etc. |

|

Our Services |

Special requirement on machining, such as threading, coaxial holes drilled and tapped, radial holes drilled and tapped, reduced shaft diameter etc. |

|

Product Package |

a. Plastic bag with box case or wooden case. We can provide shipping information to our customer at any time. |

|

Delivery Time |

3~7 days for sample order, 15~20 days for bulk order. Depends on the actual shipping situation. |

Product Description

Linear Shaft is the guiding effect of sliding bearing, which can make the products of linear motion. The necessary conditions required by the linear motion system is: Simple design, the best performance, low maintenance cost, using the selected durable material, high-frequency heat treatment, the accurate outside, diameter size, roundness, really straight and surface treatment, etc.

Linear Shaft Application

1. Solid shaft

Generally applicable to industrial robots, as a professional measuring instruments, medical equipment, precision machine tools, aircraft shaft, pneumatic mandrel movement part.

2. Hollow shaft

With its weight to reduce equipment, simplify the structure of the advantages, you can then wear the internal measurement of wire, compressed air, can also add lubricants and hydraulic oil.

3. Stainless steel shaft

It's generally suitable for use as a part of the measurement in the presence of chemicals such as chemicals, seawater and other substances. Special machining shafts are finely finished after heat treatment with hard chrome plating for all types of automation equipment.