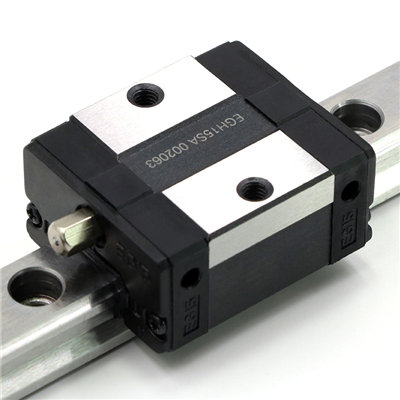

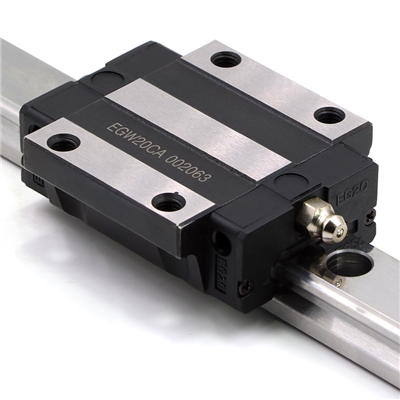

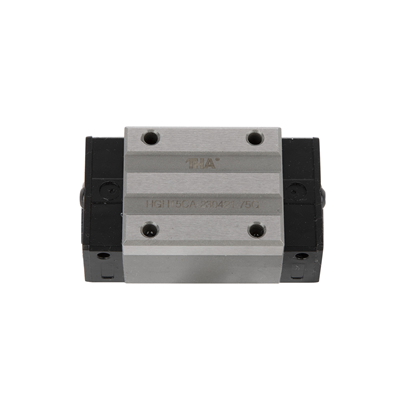

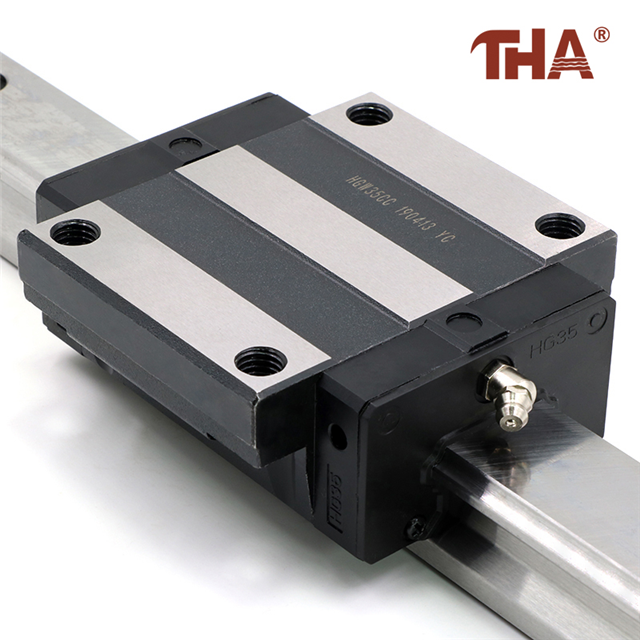

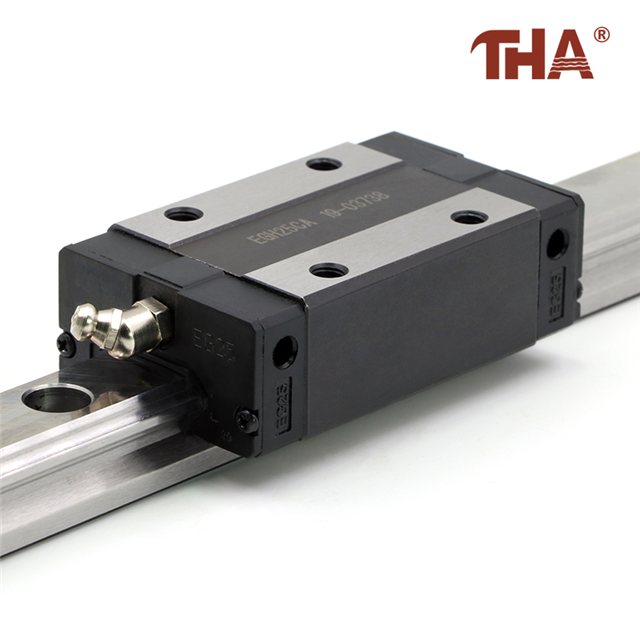

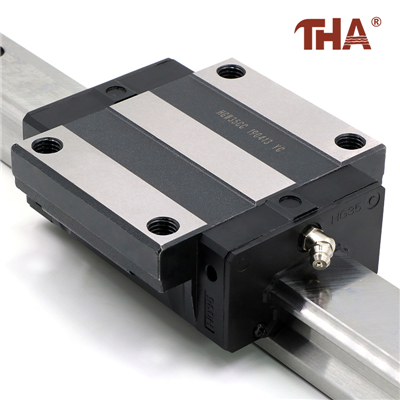

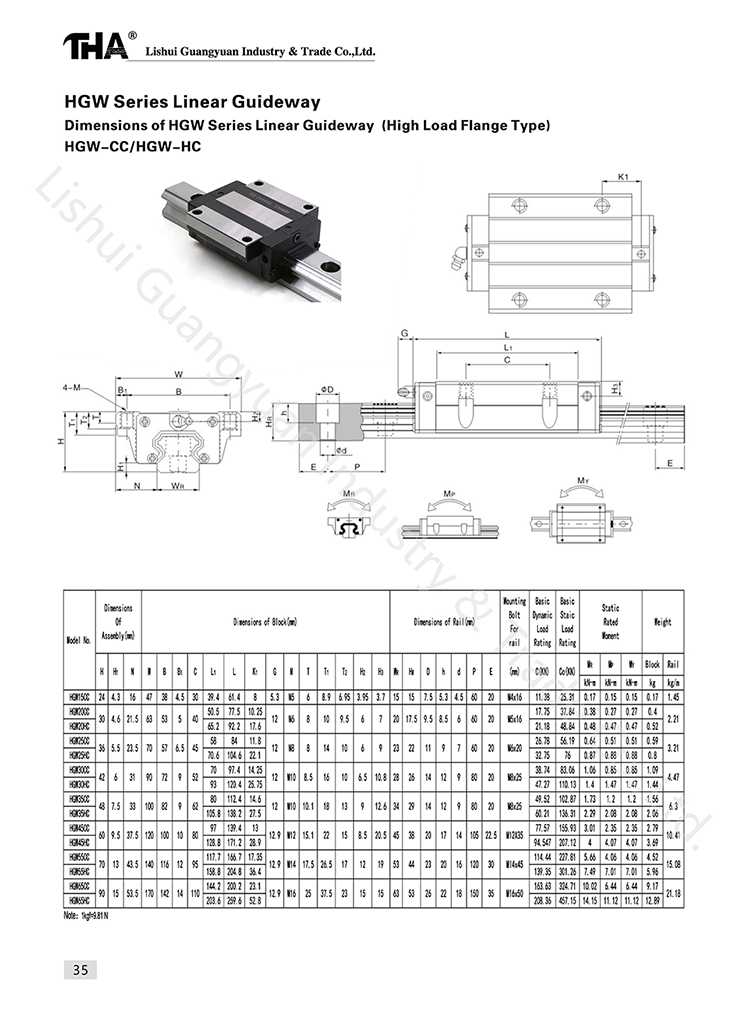

Linear guide systems comprise components such as rails, sliders/blocks, rolling elements (balls or rollers), retainers/end caps, and sealing devices. The rail serves as the fixed reference component, while the slider performs linear motion along it via internally circulating rolling elements, thereby achieving high-precision, low-friction guidance functionality.

Working Principle: As the slider moves along the guide rail, the internal balls or rollers roll between the guide rail raceway and the slider raceway, creating rolling friction. Continuous circulation of the rolling elements is achieved via reversing devices or recirculation channels, enabling the slider to perform unlimited reciprocating motion. This mechanism, which replaces sliding friction with rolling friction, reduces the coefficient of friction to 0.001–0.003. It delivers high transmission efficiency and positioning accuracy at the micrometre level.

Company Profile

Contact Us

FAQ

1.Q: Could you send me your catalogue and price list?

A:As we have more than hundreds of products,it is really too hard to send all of catalogue and price list for you. Please inform us the style you interested, we can offer the pricelist for your reference.

2.Q: Can you provide custom sizes or OEM service?

A: Yes. We offer OEM and ODM services. Custom dimensions, hole spacing, shaft lengths, materials, and branded packaging are all available. Just send us your drawing or requirements.

3.Q: Can you supply complete linear motion kits?

A:Yes. We provide full sets including:

A.Guide rails + blocks

B.Linear shafts + shaft supports

C.Ball screws + nuts + end supports

Everything is matched for smooth and easy installation.

4. Q:What is MOQ?

A:For inventory items, no minimum order quantity .

For other items, would you please check our specific details for each item to get the MOQ. Any special requirement, please tell us.

5.Q:How to contact us?

A:You can chat with us online, call us, send us email, send messages via trade manager, wechat, whatsapp, etc.