The diaphragm coupling can compensate for the axial, radial and angular deviations between the active machine and the driven machine due to manufacturing errors, installation errors, load-bearing deformations, and the effects of temperature rise changes.

Product Description

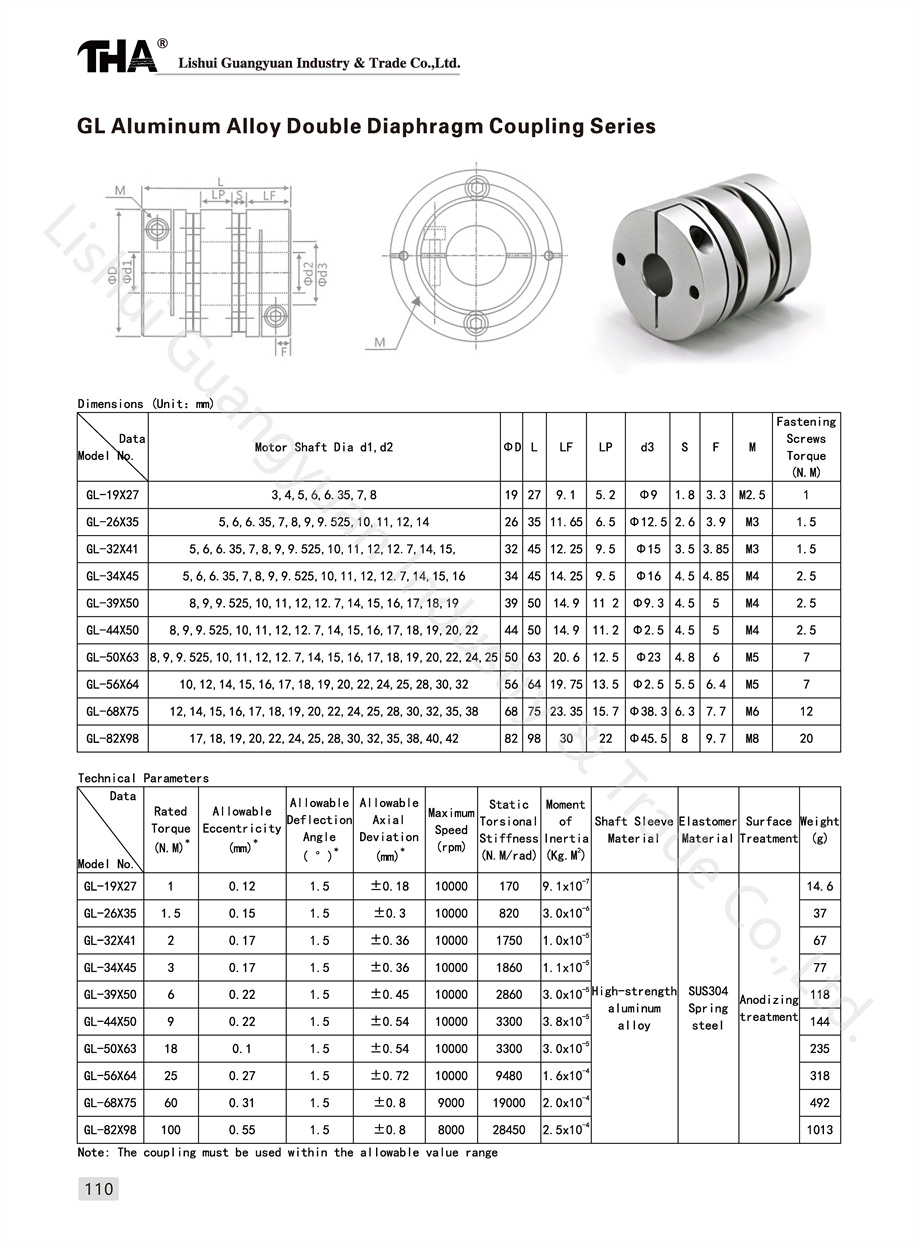

The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves. The diaphragm is fastened to the sleeve with a pin and generally will not loosen or cause backlash between the diaphragm and the sleeve. Some manufacturers provide two diaphragms, and others provide three diaphragms, with one or two rigid elements in the middle, and the two sides are connected to the shaft sleeve. The difference between the single diaphragm coupling and the double diaphragm coupling is the ability to handle various deviations. In view of the complex bending of the diaphragm, the single diaphragm coupling is not suitable for eccentricity. The double diaphragm coupling can bend in different directions at the same time to compensate for eccentricity.

|

Product Information |

|

|

Product Name |

Servo Motor Coupling |

|

Material |

Aluminum Alloy |

|

Application |

Products are widely used in automation equipment, placement machine, laminating machine, automationWelding assembly equipment, instrumentation, medical equipment, printing equipment, precision machinery equipment, grinding machines, and automatic machinery equipment Manufacturing, all kinds of non-standard production lines, etc. |

|

Model No. |

GL19x17, GL26x35, GL32x41, GL34x45, GL39x50, GL44x50, GL50x63, GL56x64, GL68x75, GL82x98 |

|

Our services |

According to drawings or samples for our customers to manufacture products. We can support OEM/ODM services. |

|

Product Package |

a. Plastic bag with box case or wooden case. We can provide shipping information to our customer at any time. |

|

Delivery time |

3~7 days for sample order, 15~20 days for bulk order. Depends on the actual shipping situation. |