Due to different structures and materials, the couplings used in the transmission systems of various mechanical products have very different load-bearing capacities. The load category is mainly for the impact, vibration, forward and reverse rotation, braking, frequent start and other reasons of the working load of the working machine to form different types of loads.

Product Description

The load category of the traditional system is the basic basis for selecting the type of coupling. For working loads with large changes in impact, vibration and transmission, a flexible coupling with elastic elements, that is, an elastic coupling, should be selected to buffer, reduce vibration, compensate for axis deviation, and improve the performance of the transmission system. The torque during frequent starting, forward and reverse rotation, and braking is several times the torque during normal and stable work. It is overload work, which will inevitably shorten the service life of the coupling elastic element. The coupling only allows short-term overload, generally short-term The overload shall not exceed 2~3 times of the nominal torque, ie [Tmax]≥2~3Tn.

|

Product Information |

|

|

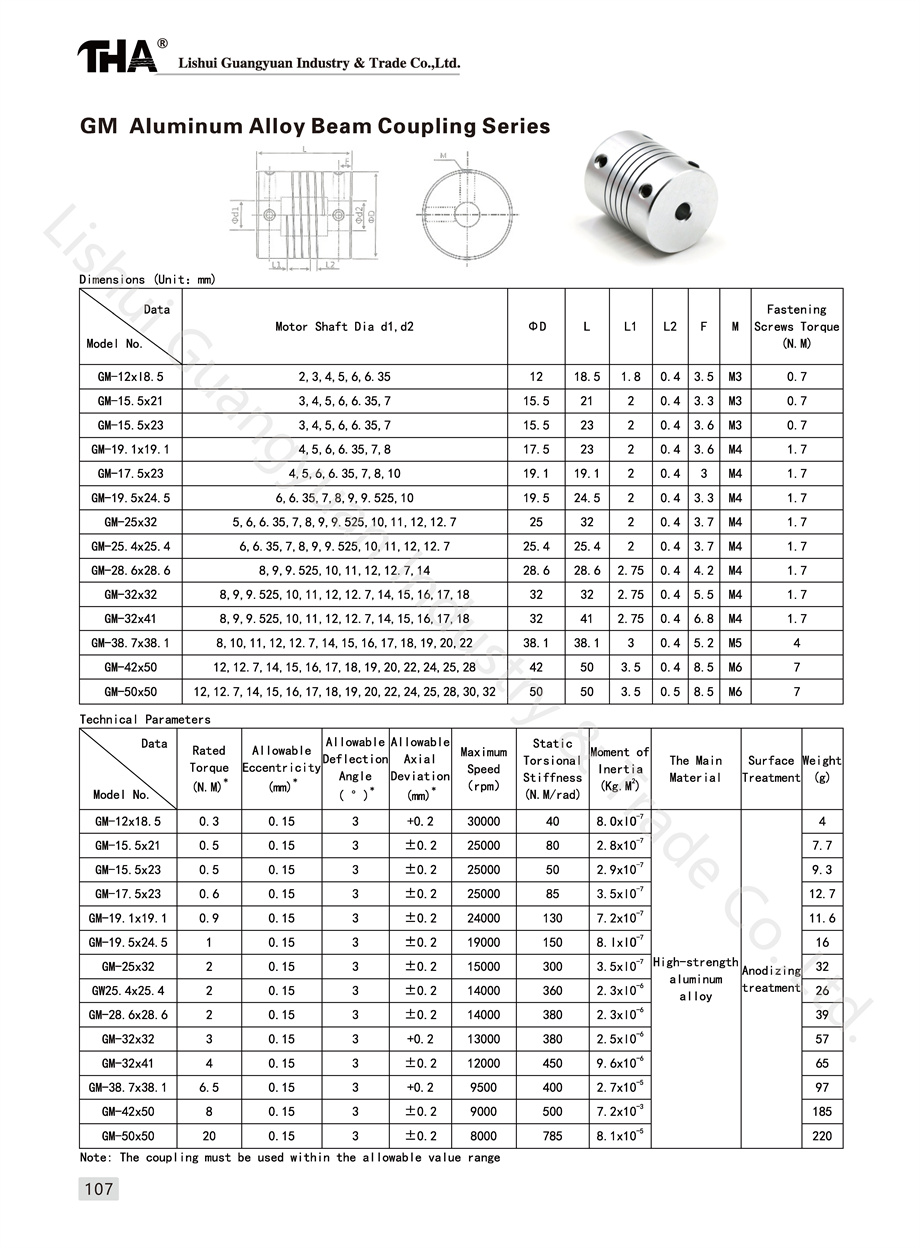

Product Name |

Stepper Motor Coupler |

|

Material |

Aluminum Alloy |

|

Features |

1. Integrated structure, the whole adopts high-strength aluminum alloy material 2. The elastic action compensates radial, angular and axial deviations 3. Spring design, with buffering effect 4. Designed specifically for encoders and micro motors 5. Fastening method of positioning screw |

|

Model No. |

GM12x18.5, GM15.5x21, GM15.5x23, GM19.1x19.1, GM17.5x23, GM19.5x24.5, GM25x32, GM25.4x25.4, GM28.6x28.6, GM32x32, GM32x41, GM38.7x38.1, GM42x50, GM50x50 |

|

Product Package |

a. Plastic bag with box case or wooden case. We can provide shipping information to our customer at any time. |

|

Delivery time |

3~7 days for sample order, 15~20 days for bulk order. Depends on the actual shipping situation. |